Commercial Roof Level Inspection & Rectification Works

Solgen were asked to carryout a roof level inspection on this 50kWp PV installation due to poor generation from insulation faults.

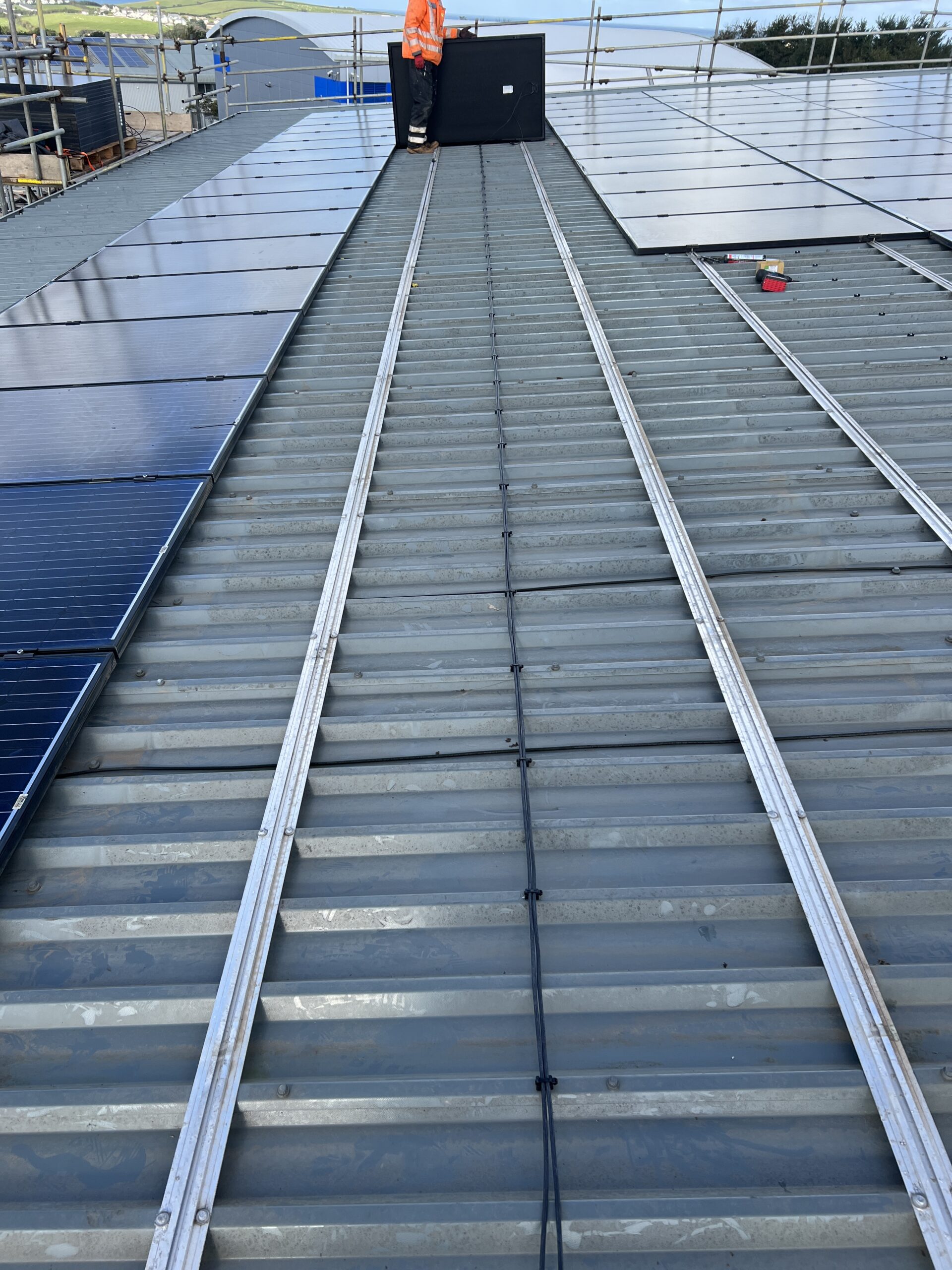

As there was no string layout diagram available the decision was made to remove all 187 modules and replace the string cables back to the Inverters. All modules were tested individually and any damaged/corroded connectors were replaced. Thermal imaging of the array was also carried out prior to removal of the modules to check for damaged cells & bypass diodes.

All cables and connectors were then repositioned and supported so that there was no contact with the mounting structure and roof surface to prevent water ingress and possible issues in the future. The cabling from the array back to the Inverter was installed in conduit to prevent UV damage and cable degradation. The array was split in the middle to provide easier access for module cleaning.

The system was then fully tested before re-energisation.

String identification was added at the Inverters and a layout diagram was provided to the customer for future maintenance works.